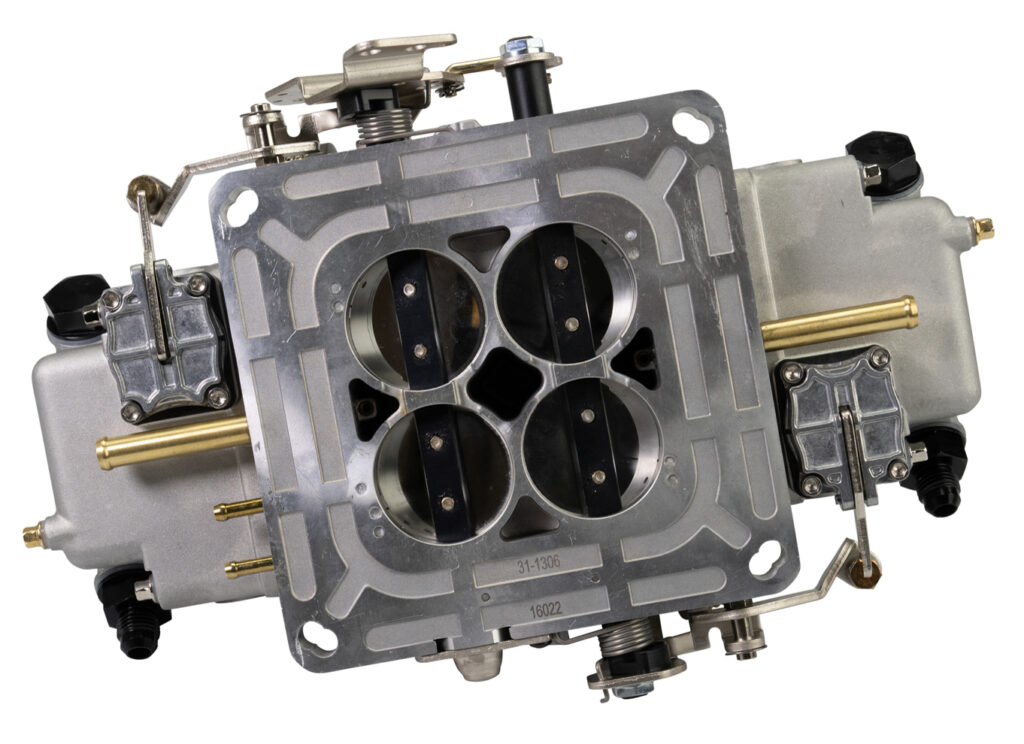

The new Edelbrock VRS-4150 Carburetor series may seem familiar to you. Yes, we have heard the “it looks like a (insert manufacturer here)” line. However, looks can be deceiving. We would not fault you for seeing the resemblance but do not overlook the VRS-4150 as a knockoff. Modular carburetors have been around for years, and many different carburetor manufacturers utilize the non-proprietary, tried-and-true platform. Looking closer, you will see that the VRS-4150 is a total rethink of everything you’ve ever thought about the recognizable modular carburetor.

Edelbrock has been in the carburetor business almost from its inception. Thousands of Performer and AVS2 series carburetors are being used in every application imaginable. They both look pretty different than most carbs on the market; there is no mistaking them. So, the question becomes, why would Edelbrock make a new carburetor that looks like so many others?

We sat down with Edelbrock Group Product Development Engineer Wesley Cameron and Carburetor Product Manager Brent McCarthy to talk about the VRS-4150 carburetors and what makes them the most economical and best high-performance carbs on the market to date. You will find it is a unique piece that is sure to be adopted in many racing and street applications.

Why A New VRS-4150?

“As to the question of why, it is pretty simple,” McCarthy says. “For more than 30 years, Edelbrock has been the solution for hot rod carburation. We needed something that offered more tunability for racers but was still street-friendly for high-performance enthusiasts. The Performer and AVS2 are terrific plug-and-play carburetors with some adjustability built into them, but racers need even more. The VRS-4150 is our answer to help those customers.”

The target market for this carb series is definitely the racer/performance enthusiast who wants to squeeze out every last bit of performance from their vehicle. Will it work for your average Joe who just wants an excellent carburetor? Sure. But, if you do not foresee yourself tinkering with your fuel flow, the VRS series might be overkill for your needs.

Cameron says the VRS-4150 is just as much a universal carburetor as the other two and should work straight out of the box with no (or little) adjustments. He has one of the prototypes on his daily-driven ’67 Cougar with only a jet change. He loves how it performs but warns that the VRS-4150 has no choke, so cold starts can sometimes be a bit ornery. Cameron says that the beauty of the VRS is the bells and whistles, but they are not necessary for the average carb user.

Why Go Modular?

The word “innovate” means to make changes to something established, especially by introducing new methods, ideas, or products. In developing the VRS-4150, Edelbrock engineers consciously decided to use the modular carburetor platform. Much like the adoption of pneumatic tires on wagon wheels, they saw plenty of places where the original invention could be improved. A modular carburetor is familiar to most performance enthusiasts, so they saw no reason to reinvent the wheel and educate customers on their function.

What makes a modular carburetor “modular” is the ability to interchange or replace parts. While some parts of the VRS could technically interchange with other companies’ carburetors, chances are they may not work as intended, even though they may bolt up to them. So, even though they may look the same, the VRS-4150 is very different from a design perspective.

Five Reasons Why The VRS-4150 Is Better

Other carburetors on the market have some attributes of the VRS series, but you will be looking at a significantly larger price tag. Some videos, like this one from Muscle Car Solutions and a great article by Jeff Smith, explain all the new aspects of the VRS-4150 series, so we won’t go into great detail here. Instead, we thought we would give you five reasons why the VRS-4150 is a step up for carburetors in the performance market at a fraction of the cost.

1. More Average Power

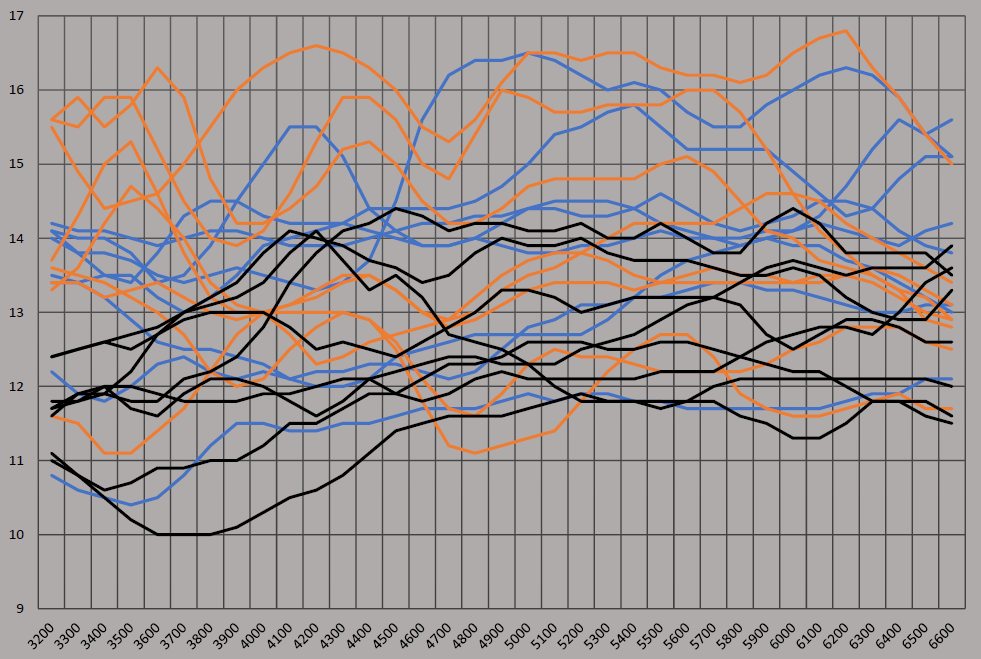

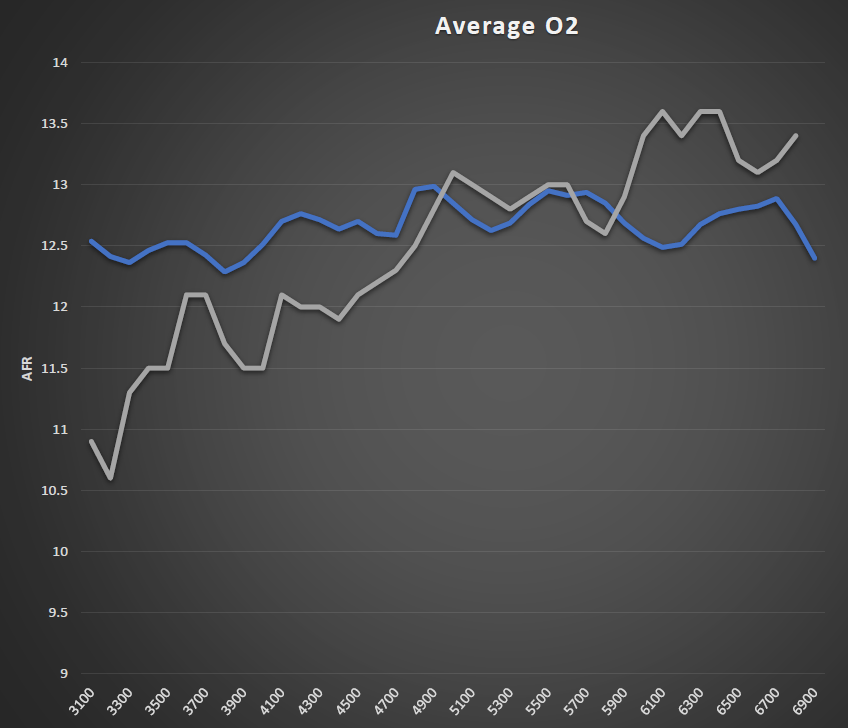

On a V8, every cylinder is responsible for one-eighth of the power production. So, if one cylinder is at a 15:1 air-fuel ratio (AFR) for an entire wide-open-throttle (WOT) pull, and it makes 50 percent of the theoretical max power of that cylinder, the engine loses one-sixteenth of the total power output.

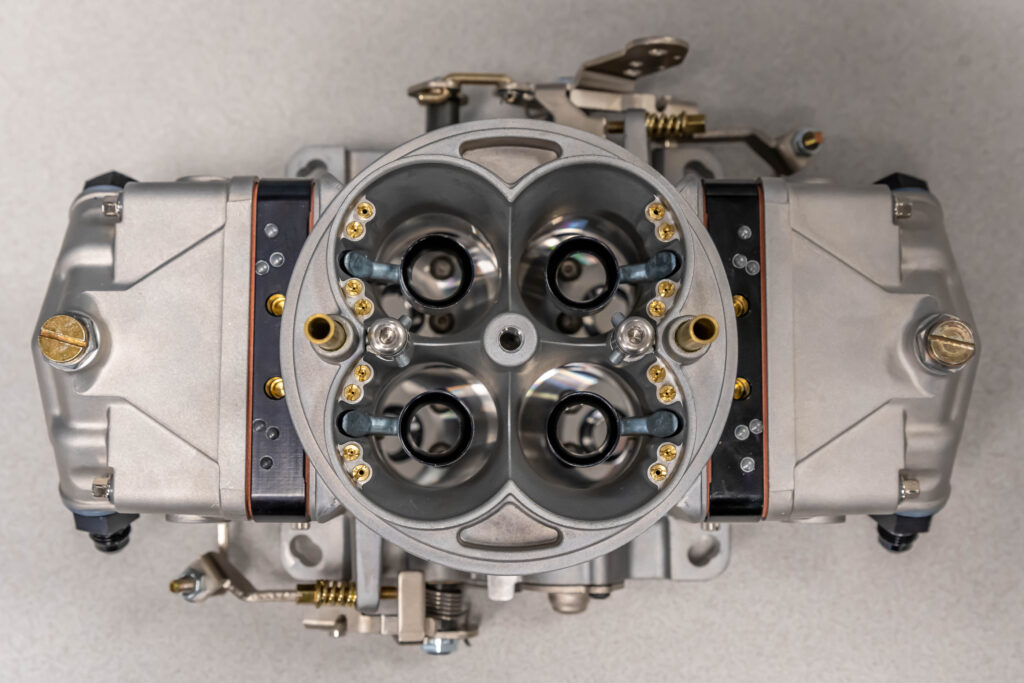

Compared to port or direct injection, the challenge for carburetors and throttle bodies is to distribute fuel evenly across cylinders. However, the VRS-4150 is one of the best in the category of cylinder-to-cylinder distribution. Testing shows the VRS-4150’s large annular boosters (and likely, the taller venturi) atomize the fuel better before introduction into the manifold, resulting in a much more even distribution across cylinders.

During WOT, engines make the best power between 12.5-12.8:1 AFR, depending on your source. The powerplant is not making max power for every decimal place away, and every RPM not in that range, either above or below. In a side-by-side comparison with a competitor’s carb, the VRS-4150 maintained a much flatter average O2 curve right out of the box.

2. More CFM

The VRS-4150 is ½-inch taller than any other carburetor on the market. That extra height creates a better venturi design that flows more air than a standard carb. Wesley Cameron believes this likely helps with atomization as well. They are currently evaluating the effects on atomization and should have statistics on it shortly.

3. Leaner Cruise

Though the VRS-4150 is marketed as a racing carburetor, the adjustability built into the series is why it is so universal. The VRS can be tuned to cruise at almost any AFR desired using the idle discharge jet.

4. Better Base Calibration

Like other Edelbrock carburetors, the VRS series has an excellent out-of-the-box base calibration. The Performer and AVS2 series carbs have always been known for being great right out of the box — bolt them on and go. You can expect the same performance from the VRS series. The only difference is that it has no choke, so it may take a while to warm up.

5. Starve No More

A ton of research and development went into the VRS-4150 series float bowls. Not only are they larger than standard bowls by approximately 25ml, but everything is designed to keep the main jets submerged in fuel. This is excellent news for those who road race, autocross, or just like to carve corners in the canyons.

Fuel starvation is often an issue for carburetors in these environments. With hard cornering, fuel slosh can submerge the float for more extended periods over average or straight-line driving. Also, g-forces can keep the float pinned down in long corners. If the float remains down for too long, the pump cannot fill the bowl quickly enough to keep the jets supplied, and the car stalls.

The VRS-4150 bowl designs incorporate a few trick ideas to prevent this. A “mustache” under the needle and seat serves two purposes: 1) it deflects fuel coming in from the top toward the sides of the bowl, and 2) it serves as a baffle for fuel sloshing up from the bottom to deflect it back down away from the needle. There are also baffles built into the sides of the bowl to keep the majority of fuel from inundating the float.

Engineers developed the float to keep it on top of the gas. While the entire float is tapered toward the pivot arm, the bottom corners are also tapered inward to keep the corners of the float from getting pushed down by the fuel in cornering. Also, jet extenders come standard in the rear bowl to keep the jets under during hard acceleration. Two notches through the center of the float bowls to accommodate the extenders have also proven to help baffle the fuel when moving side to side.

It is not uncommon to see a carbureted car stumble during hard cornering or braking. However, Cameron tells us that real-world testing on his ’67 Cougar and a friend’s ’71 Dodge Demon during multiple autocross events proves the float bowl design does its job. “We both have VRS carbs on our cars. Both cars can corner at close to 1G, and neither of us has seen a single fuel starvation issue to date,” he says.

Other Reasons To Consider the VRS-4150

We only touched on a few design elements that make the VRS-4150 one of the best carbs ever built, especially at the price point. However, several more aspects set it apart. While they are not performance enhancements, the dual sight glasses and drain plugs on the float bowls are game changers when it comes time to adjust the level and change jetting. A TPS sensor hookup is built into the flange, making communication with data loggers and electronic transmissions easier. The air bleeds on the top are easy to reach and are trick, especially for those using an air-fuel meter.

There are also a few updates on the horizon. Cameron tells us there will be an 850 and 950 carburetor, probably by the SEMA Show 2023. The annular boosters were built to be removable and changeable, so there will be options there, too, as they work with engine tuners who want different choices. Be on the lookout for more information as engineers continue refining the VRS-4150 series of carburetors.