Many aftermarket techs often receive questions on increasing fuel mileage in regularly driven performance vehicles. Most of these vehicles are street/strip applications using flat tappet cams, carburetors, and non-lockup transmissions. These older technologies may be the cause of greater fuel consumption. However, there are some things you can do to improve fuel mileage while still getting the most out of your ride.

The ability of today’s cars to run more efficiently is directly attributable to new technologies. Although, there is no reason a classic street/strip application can’t perform well on the track and still retain good fuel mileage for daily driving. In these older cars, reducing friction and increasing fuel mileage is possible by upgrading some key areas in the drivetrain, fuel delivery, and to a lesser extent, the valvetrain. Changing just one of these will help, but the benefits are increased with every upgrade, and every little bit helps.

Shift Into Mileage Overdrive

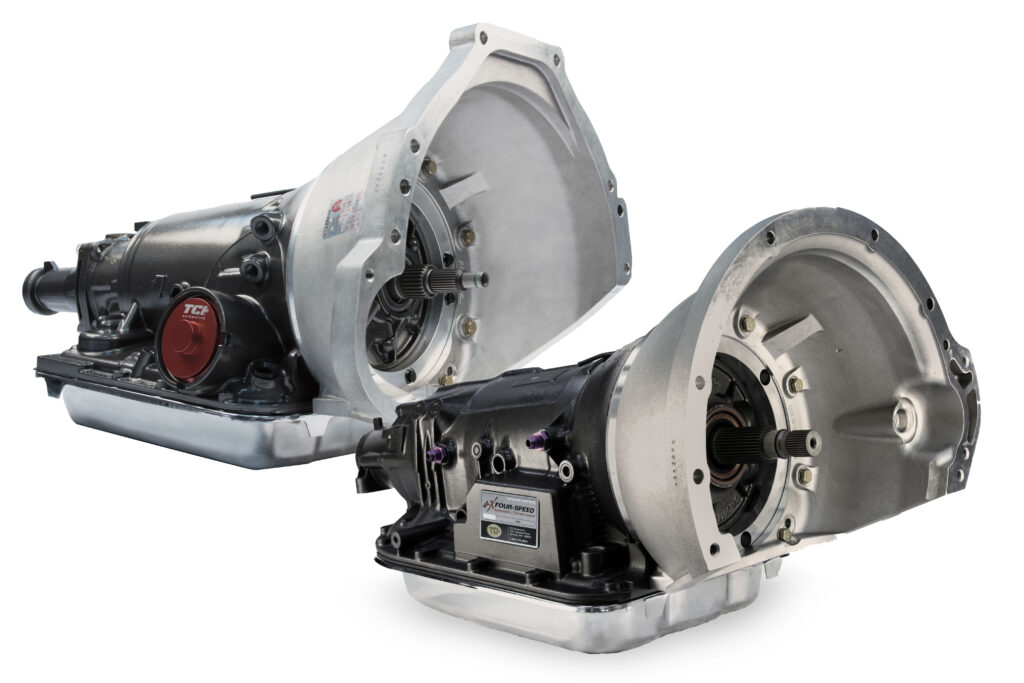

One of the most significant areas to noticeably increase fuel economy without adversely affecting performance is in the drivetrain. Whether manual or automatic, an overdrive transmission will increase fuel mileage by decreasing engine RPM, thereby increasing the engine’s life. Additionally, the gear ratios of overdrive transmissions provide a more efficient spread to complement the ring and pinion.

Overdrive transmissions allow you to lower your final drive ratio for highway cruising but still have jackrabbit starts to get the car moving. With an overdrive, you can have more low-end torque to get the vehicle moving quicker, lower top-end RPM, and better fuel economy — the best of both worlds. Nowadays, there are so many options for customers — they no longer have to stay specific to a make when it comes to a transmission, either. TCI Automotive offers its 4X StreetFighter transmission based on the robust GM 700R4 (manual) or 4L80E (electronic) platforms with adapters to fit most popular V8 engines.

Though they may seem a little more complex, electronic automatic overdrive transmissions such as those offered by TCI are the way to go for ultimate adjustability. Utilizing a transmission controller like the EZ-TCU enables maximum electronic control over shift points, shift firmness, and shift speed. The unit is fully programmable, allowing users to adjust each of the parameters on the fly based on load, speed, and RPM.

The Transfer Of Power

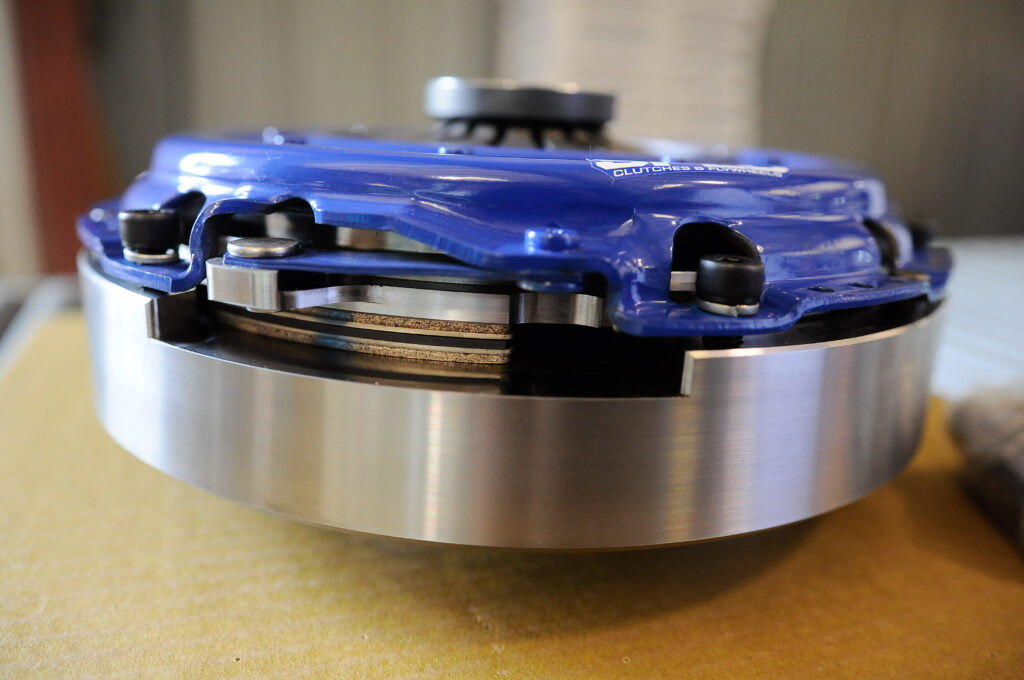

Another piece of the drivetrain puzzle that can significantly save on fuel consumption for automatic transmission cars is the torque converter. Much like a clutch in a manual, a torque converter’s job is to smoothly transfer the rotating power of the engine to a driven load (the transmission). Though their job is the same, they work in slightly different ways to achieve the goal. A clutch is a mechanical device, whereas a torque converter is a hydraulic device. This distinction is an important one to make for the purpose of fuel mileage.

Clutches

In the not-so-distant past, a car with a clutch was more fuel efficient. For the most part, you can think of a clutch as either engaged or disengaged. A properly working engaged clutch turns at the same speed as the engine. The only slippage of the clutch disc occurs during gear changes and is controlled by the driver’s foot. Heat is only generated while the clutch disc slips against the flywheel and pressure plate.

Fluid Couplers

On the other hand, older automatic transmissions depended on fluid dynamics to transfer power from the engine to the transmission. Early cars were equipped with a fluid coupler made up of a radially straight-bladed impeller and turbine. The coupler was always in a state of “slip” — the impeller turned faster than the turbine. Fuel mileage was not as much of a concern back then, and fluid couplers were smooth but relatively inefficient and subject to heat issues.

Torque Converters

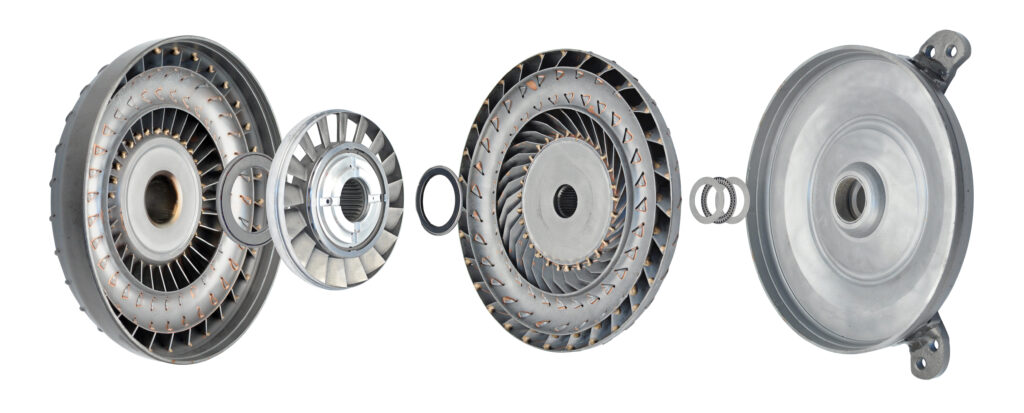

The next step in the evolution of power transfer saw the introduction of the torque converter. Like a fluid coupler, a torque converter has an impeller and a turbine, but with angled and curved blades. It also adds an angled/curved-bladed stator between the two that multiplies the torque by altering the oil flow into the turbine. Some converters even incorporate multiple stators or variable-pitch stators to improve torque production and/or efficiency further.

With the extra pressure created from the friction and turbulence of fluid redirection, these converters generated quite a bit of waste heat at stall. Still, they were more efficient at speed, resulting in better mileage. Regardless, the power was never transferred at a 1:1 ratio in these older setups and still left room for greater efficiency.

Lockup Converters

Modern technology introduced lockup converters to combat the parasitic loss associated with their traditional brethren. A lockup converter adds a device (a clutch on most cars, *see sidebar) to the equation allowing the turbine to lock with the impeller and spin at the same speed, eliminating losses associated with a fluid drive. The result is virtually no power loss or slippage, improved efficiency at speed, and heat reduction. Though Packard introduced the first lockup converter in 1949, it really didn’t come into favor until the ’70s and is now almost universally used with automatic transmissions.

A lockup torque converter will generally reduce RPM by around 400, which will usually increase fuel mileage over a standard non-lockup torque converter by about one to three miles per gallon. For example, if a stock torque converter setup runs at 2,600 RPM while driving 65 MPH, upgrading to a TCI overdrive converter lowers engine RPM to around 2,200 at the same speed, thereby increasing fuel economy on the highway.

It makes sense to change the converter if you are already installing an overdrive transmission. Combining a lockup converter with an overdrive transmission will multiply the fuel mileage savings. Switching from a non-lockup three-speed transmission setup to a four-speed lockup transmission with a properly matched torque converter will gain about five to seven MPG on the highway.

Sidebar: Early Ford AOD transmissions introduced in 1980 used a torque converter that did not use a clutch for the lockup mechanism. Instead, it is essentially a direct drive. When shifted into Third gear, the transmission has a shaft that engages into the torque converter, making it a 1:1 ratio with the transmission. The Third gear band stays on when the overdrive band comes on for the 0.67:1 Fourth gear.

TCI Automotive General Manager Scott Miller says the transmission/converter combination worked well for a stock setup but proved a bit of an Achilles heel when bumping up the engine’s horsepower. “It’s interesting how they did it, but it’s just not the best way,” he says. “It can break the mechanical part to lock it up in the converter as well as the tiny shaft used to do it. Ford went to a converter clutch when they went to the AODE. If we build converters for the AOD now, we reinforce it internally and sell a Vasco shaft for the transmission. However, we try to steer customers toward our more reliable 4x transmission, which is a 700R4 or 4L80E that can bolt up to just about any transmission.”

Fuel Delivery

Carburetors

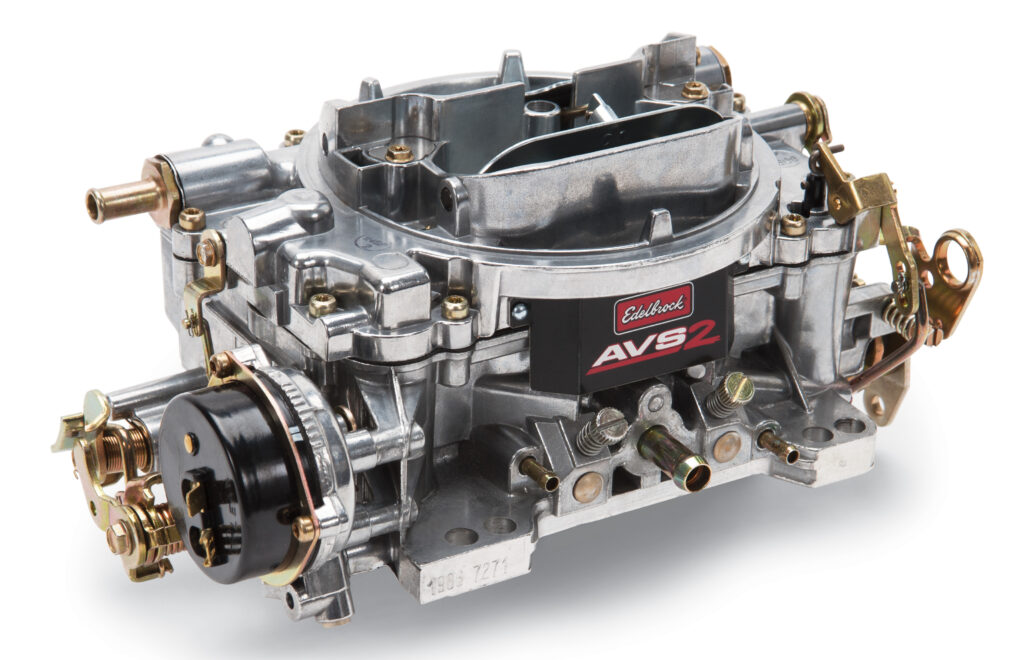

Fuel delivery is another significant area where you can gain some extra mileage. The most obvious is to switch to EFI, but if you want to stay carbureted, you can still do a few things to improve fuel economy. We asked Edelbrock Group Product Manager Brent McCarthy what someone could do.

“I recommend getting a good air/fuel ratio gauge,” he says. “Use it to adjust the tuning hardware [metering rods, jets] to achieve a mid-13’s air/fuel ratio at cruise. The accelerator pump circuit delivery is 25cc per 10 strokes on the outer hole, 31cc on the middle hole, and 39cc on the inner hole. Use the least amount of shot to get acceptable acceleration. You should also use a vacuum gauge to set the idle mixture per the instructions in the owner’s manual. Lastly, use a good clean air filter.”

FAST sells two excellent wide-band air/fuel meters with single or dual sensors to get the full story of your engine’s performance. The dual units allow the owner to read the exhaust oxygen sensors separately for precise adjustments or averaged together. Either choice will give you accurate real-time data that you can use to adjust your setup for maximum fuel economy.

The FAST Gasoline Air/Fuel Meter [P/N 170401 (single), 170402(dual)] is a wired unit that includes a simple, built-in data logger that you can view in real-time on the handheld. Meanwhile, the FAST Wireless Air/Fuel Meter Kit [P/N 170301(single), 170302(dual)] is a revolutionary app-based wireless Bluetooth meter that uses an under-hood-mounted module to connect to the oxygen sensors. It comes with preloaded fuel calibrations for measuring gasoline, popular ethanol brands, methanol, diesel, and more. You can conveniently view the information on an iOS or Android device.

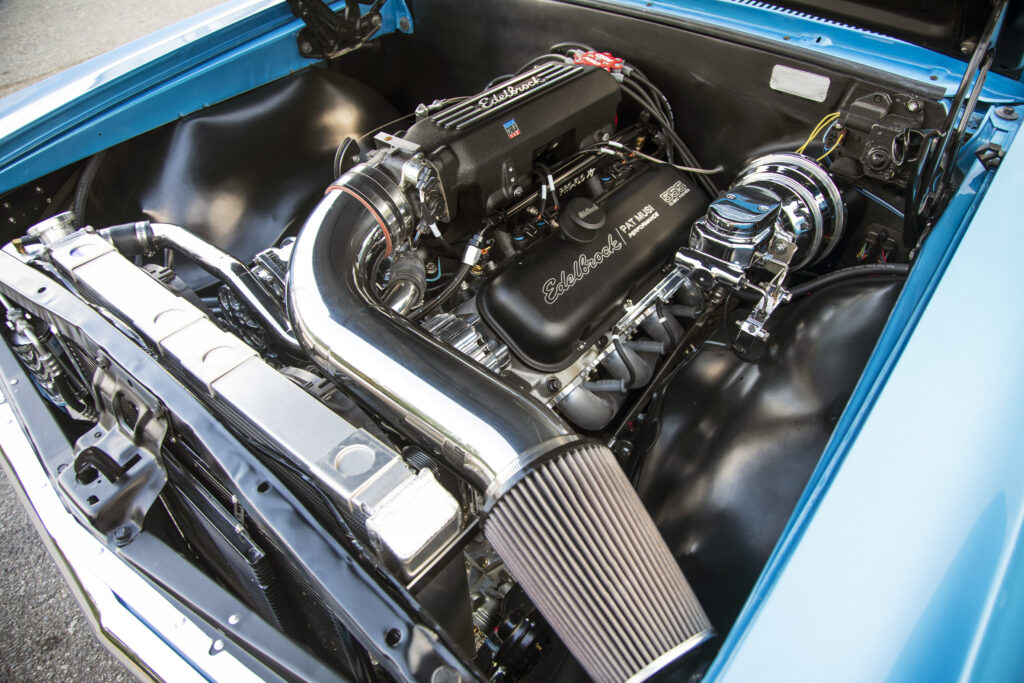

Electronic Fuel Injection

There are specific situations where carburetors can be tuned to work better than electronic fuel injection. However, it’s common knowledge that, overall, EFI is more fuel efficient than carburetion. A properly configured electronic fuel injection system doesn’t need to be tuned or tweaked the way carburetors do either. The adjustability afforded by EFI generally wins out in the long run for your basic street driving applications.

The switch to EFI used to be intimidating to many carb fans, but with cutting-edge systems such as the FAST EZ-EFI or Edelbrock Pro-Flo 4, there is no reason not to make the switch. One of the significant reasons EFI is better is that it atomizes the fuel before it enters the combustion chamber. If you don’t want to change your manifold, you can choose a throttle-body system that takes the place of a carb. Or, for even greater precision, you can select a manifold rail-style system with injectors sitting in the runners right above the chamber.

EFI analyzes the burnt fuel mixture through sensors in the exhaust and continuously adjusts the amount of fuel delivered through the injectors for optimum performance. “Performance” in this situation equates to the fuel-burn efficiency for the given throttle input. In other words, the EFI always aims to hit the target air/fuel ratio.

Paired with a smart ignition, an EFI system controls the fuel delivery as well as the timing to keep adjusting the mixture regardless of changing conditions. Advanced systems such as EZ-EFI and Pro-Flo 4 will even correct themselves for changes in altitude and weather, providing the best mileage possible no matter what, which is something a carburetor is simply incapable of.

Some customers have reported up to six miles per gallon more over carburetors after installing an EZ-EFI Self-Tuning Electronic Fuel Injection System. While everyone may not experience quite that big of an increase, fuel mileage will almost always increase when upgrading to EFI over a carburetor. Pair that with snappier throttle response, improved cold starts, and more power, and you can see how switching to EFI gives you the best of everything.

Valve Train

The valve train is one area many people think of upgrading when looking for more power but seldom think of when wanting fuel mileage. While it may not benefit you as much as the drivetrain or fuel delivery (and there isn’t a ton of comparative research out there regarding upgrades for fuel mileage), it’s worth a look. Especially if you are considering upgrades in the valve train anyway, this may give you some food for thought.

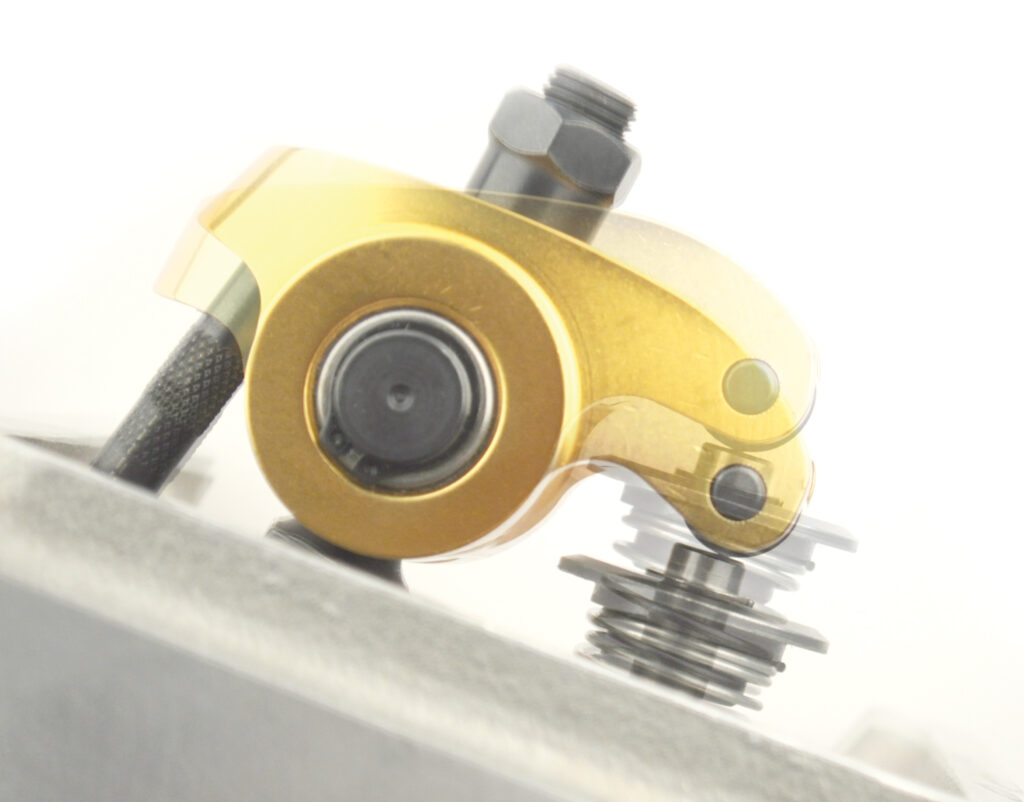

Simply put, the valve train is the mechanical system that controls the opening and closing of the intake and exhaust valves. It consists of the camshaft, tappets (lifters), pushrods, rocker arm assemblies, and valves. The two parts that probably have the most significant impact on fuel efficiency are the cam and rocker arms. To a lesser extent, the lifters could play a role, mainly when used in conjunction with the other two.

We spoke with COMP Cams Product Manager Chris Potter about some of the development and engineering in the valve train realm and how technology is creating more efficient engines. Potter tells us that a significant friction saver has been the development of trunnion rocker arms to replace many of the stock powdered metal sets. “Much of the work the OEs have done over the last several decades has also involved reducing friction in the engine. One of the best things they’ve done is something the aftermarket created early on when they popularized the roller trunnion rocker arms,” Potter says.

“Looking at almost all modern pushrod engines, the rocker arms have a slider tip but include a needle-bearing fulcrum where the rocker arm pivots,” he continues. “Removing the old ball-and-socket-style rocker arm pivots got rid of a significant source of friction within the valve train. Far more, in fact, than the roller tip in place of the slider tip. We’ve also done some significant work on [cam] lobe families that will aid in throttle responsiveness and drivability. While we haven’t done fuel efficiency testing specifically, I would be surprised if some of that work doesn’t benefit efficiency in the long run. “

In fairness, most testing at COMP is being performed on newer, more modern engines as opposed to the older generation families from the Big Three. However, some of those technologies will find their way into the old workhorses. So, with the idea of friction reduction in mind, the move to roller valvetrains has undoubtedly made for more efficient engines.

COMP Cams developed retrofit roller cams, lifters, and rocker arms to address flat tappets’ inherent downside. Retrofit roller setups reduce friction and drag while increasing valve train stability. Even though they may carry slightly more mass than flat tappets, the result is a smoother-running valve train without sacrificing performance.

Other Mileage Considerations

We didn’t touch on all the things you can do to increase fuel mileage here, but there are other thoughts to consider if you want to squeeze every last ounce of mileage out of your hot rod. Though we touched on the heavy hitters, many little things add up when talking about fuel mileage.

Another significant consideration is the differential gear ratio (i.e., the ring and pinion). Get a gear that complements the transmission. The game’s name is the same as it is for an overdrive transmission — getting the RPM as low as possible at highway speeds without bogging the engine. Turning high RPM equates to burning more fuel, so you will never get as good of mileage with a 5.10 gear as you would with a 3.55.

The cam profile can also play a pretty significant role in fuel consumption. So, if you are looking for good miles per gallon, don’t get an aggressive drag race cam and expect to overcome it with gearing or EFI. It’s just not possible. All of the parts must work together to some degree.

To further reduce valve train friction, a high-quality oil explicitly developed for muscle cars, such as COMP Cams Muscle Car & Street Rod Engine Oil, will improve surface mating of the rotating assembly, rod journals, piston rings, valve guides, cam, lifters, and other engine components. The more you can reduce internal engine friction, the less horsepower will be robbed, and the more efficient your engine will run — every little bit helps.

If you want to be a hypermiler, you can get really crazy. Running thinner tires yields less road friction. Removing weight from the car will help as you don’t have to move as much mass down the road. You could also remove power-robbing components such as power steering or air-conditioning if you are on the lunatic fringe. However, we want you to enjoy the experience of driving, so we wouldn’t recommend going that far off the deep end.

Hopefully, a few of these tidbits gave you some food for thought on what you can do to improve your driving pleasure. In the end, it is about figuring out what is the highest priority for your application. Do you want power, or do you want mileage? No matter what you decide, there will always be a compromise between the two, but there is technology out there that helps close the gap.