Note: While this installation is performed on a classic Ford Bronco with a V-8 engine, most of the installation procedures and performance benefits of the Edelbrock Pro-Flo 4 apply to all vehicles.

You don’t have to be a Ford fan to appreciate the capability or cool factor of a classic Bronco, the “all-purpose vehicle” that paved the way for Chevrolet’s Blazer and Jeep’s Cherokee. The first-generation Bronco enjoyed a 12-year production run from 1966 through 1977 before it was revamped into a full-size SUV for the 1978 model year. The early Bronco was Ford Motor Company’s perfect off-road stablemate to their iconic Mustang ponycar that was into its second year of production in ‘66. The Bronco and Mustang were worlds apart in design, but they shared the same V-8 engine on the option list. While Jeep’s CJ-5 remained the top seller in the small 4×4 category, Ford produced nearly 35,000 Broncos in the first two years of production. At first, early Bronco buyers were limited to a 105-horse inline six for power, but when Ford added the 289-cubic-inch V-8 option shortly into the first year of production, the small-sized SUV became an instant hit among off-roading hot rodders of the era.

Like many cars and trucks of the ‘60s, the classic Bronco is seeing a steady rise in both popularity and value as a collectible. In fact, a recent article from Haggerty reported that 1966-77 Broncos have increased in value by 200 percent over the past decade with no sign of slowing down.

While many Bronco owners stick with a utilitarian theme for their modern-day rebuilds, some guys like Michael Dorvillier want to take their on- and off-roading experience to the next level. For that, Dorvillier called upon Gateway Bronco, a facility with the space and expertise to build restored and modernized turnkey Ford Broncos on an assembly line. Located in the Midwest region of Illinois near Route 66, Gateway owner Seth Burgett oversees a team of experts who can produce any one of three different levels of badass Broncos depending on what your pocketbook can handle. Delivery time for a Gateway-built Bronco can be as short as two months, and all come with a warranty.

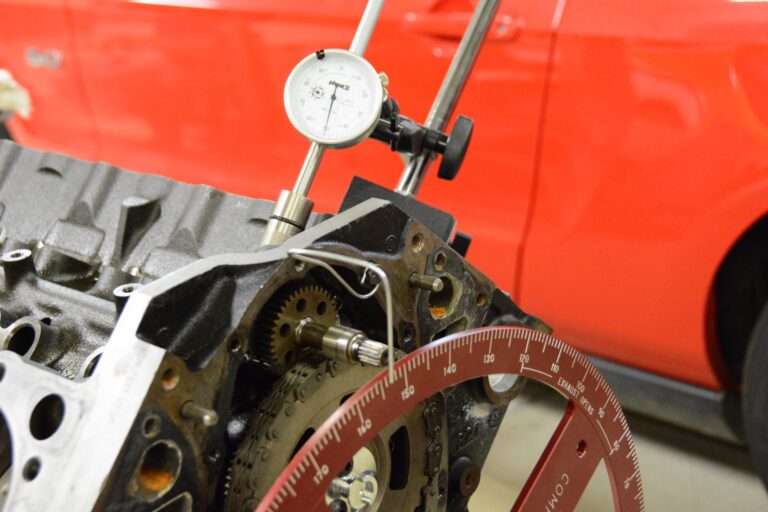

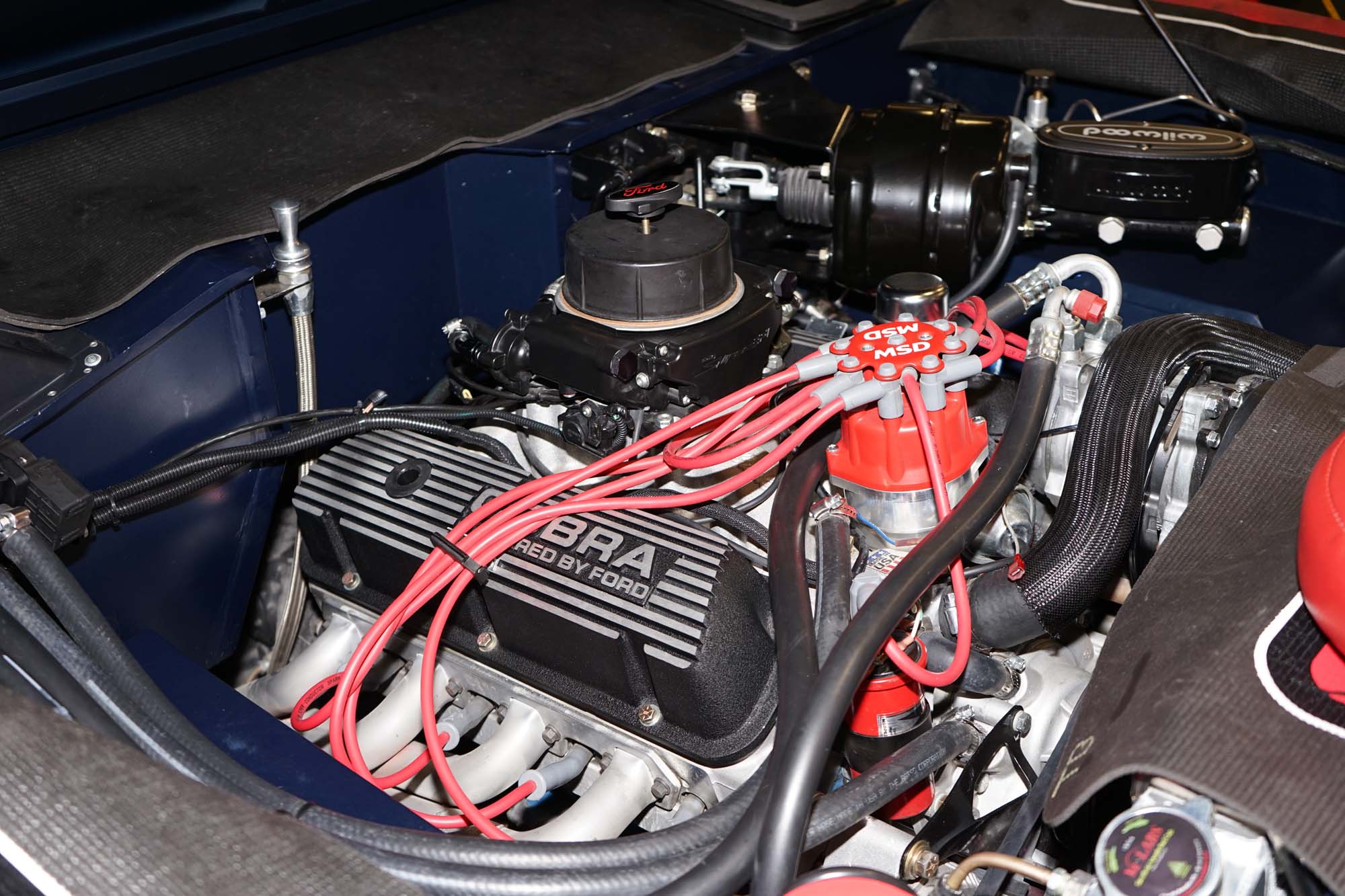

Dorvillier’s 1969 Bronco Sport is from the Gateway “Fuelie” line and, believe it or not, it’s the company’s base offering that starts at $95,000. The other two models in the Gateway lineup feature a 2018 Coyote 5.0L engine under the hood. Late-model Coyote power may be the ultimate for modern performance and reliability, but if you want a true hot rod version of the Bronco, then the Gateway Fuelie with a 302-based 347-cubic-inch stroker engine is the way to go.

The list of modifications and options on Dorvillier’s Gateway-built Bronco is as long as your arm with a fully restored and custom-painted Ford Bronco body, a custom leather interior, a stoutly modified drivetrain that includes the aforementioned warmed-over 347 Ford stroker backed by a four-speed automatic transmission, along with plenty of custom options. Up until recently, all of Gateway’s 347 engines have been fueled by Holley’s Sniper throttle body injection in an effort to add modern EFI drivability with a minimal increase in cost. But after experiencing numerous drivability issues with this and other builds with the Sniper TBI, all of that is about to change.

Owner Mike Dorvillier said the Holley Sniper TBI made the Bronco “a real chore to drive.”

Dorvillier was pleased with the power and torque that the 347 provided, but he was less than thrilled with the cold-start characteristics, stalling, and general drivability issues that the Sniper TBI-equipped engine exhibited. The stalling began to occur after Dorvillier took delivery of the Bronco so, under warranty, he sought help from an authorized repair shop in California who, after consulting with Holley, moved the idle up to prevent the stalling.

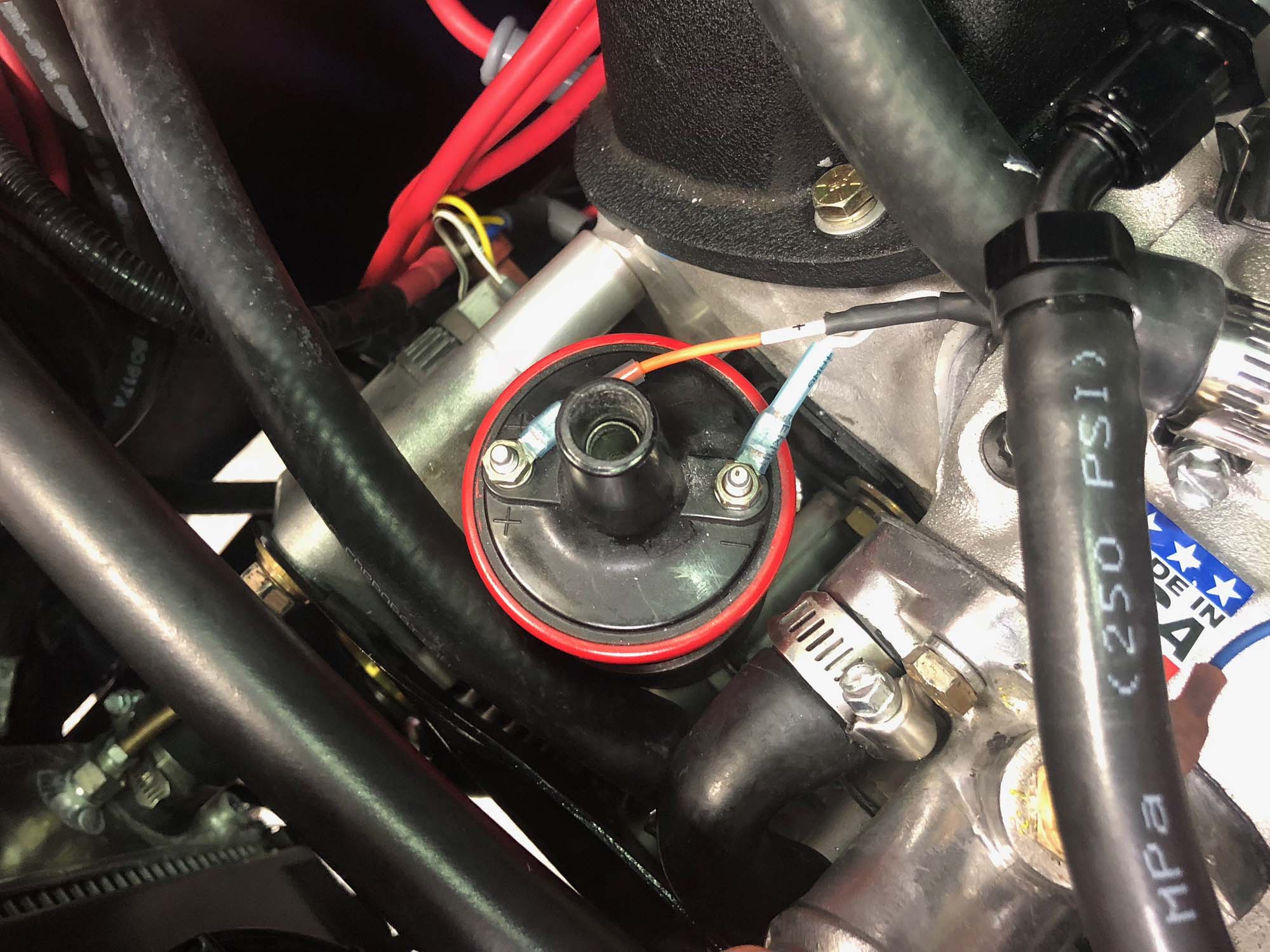

The Sniper is a throttle-body injection unit (TBI) that supplies fuel through injectors located in the throttle body. Aside from its slightly more appealing price point, another feature of a TBI kit like this is that installation can be relatively simple since it is a direct-fit, universal replacement for a 4150-style four-barrel carb and is sometimes the only solution for obscure engines that do not have a direct-port intake manifold available.

The cost factor never fails to raise this question: Are the few benefits of a TBI system worth the slight savings in cost, and more importantly, does the TBI system provide enough of an improvement over a carburetor to make it a worthwhile investment?

Learn more about the differences between TBI and multi-port EFI in this video from the Edelbrock USA YouTube channel.

SO WHY HAS GATEWAY BRONCO TRANSITIONED FROM HOLLEY TBI TO EDELBROCK PRO-FLO 4 FOR THEIR RESTOMOD BUILDS?

To get to the bottom of Dorvillier’s TBI problems, we went straight to Gateway Bronco, builders of the truck. According to Gateway President Seth Burgett, the problems that their engine department has experienced with the Holley TBI is not exclusive to Dorvillier’s Bronco. After no less than eight installations using the Holley TBI, Gateway has had key issues with each one. Burgett pulled no punches when he listed the problems that his engine department was having with the Holley Sniper TBI. The major issues were:

- SYSTEM FAILURE – Premature failure of the Sniper system in the field. Following a proper tune, it would backfire on the customer and then fail to start. This occurred with two of the eight installations.

- BACKFIRING, BOGGING AND SURGING – Tuning was erratic. Burgett said that after properly tuning, they would see lean conditions with backfire into the intake, hesitation at start, bogging under hard acceleration, and surging.

- EXCESSIVE IDLE SPEED – High idle speeds were set by an authorized independent repair shop under warranty in an effort to prevent stalling when shifting into Drive or Reverse. (Burgett says that this solution was provided by Holley Tech Support and the repair shop, not Gateway Bronco.)

- INCONSISTENCY – Throttle response with the Holley Sniper could be exceptional on one vehicle, but poor on another with the exact same engine, ignition, tires, transmission, and gearing.

- BURGETT SAID that when they tried to transfer a Sniper TBI to another vehicle to determine where the problem was, the same issues would follow the TBI unit.

From a business standpoint, it was logical for Gateway Bronco to seek out the most cost-effective EFI system for their line of classic Bronco restomods. But after trying diligently to solve multiple issues with the Holley Sniper TBI, Burgett says that Gateway Bronco has transitioned exclusively to Edelbrock Pro-Flo 4 for their EFI systems.

While TBI kits continue to be a viable aftermarket EFI option for some applications, many high-performance engine experts and hot rodders in general are moving away from TBI in favor of multi-port EFI simply because they feel that TBI is a rudimentary system and nothing more than a glorified carburetor since it delivers fuel into the air stream at the plenum directly below the throttle body, just like a carb. With TBI, fuel is not equally distributed to all the cylinders, oftentimes puddling at the plenum. This means that the air/fuel mixture injected differs for each cylinder.

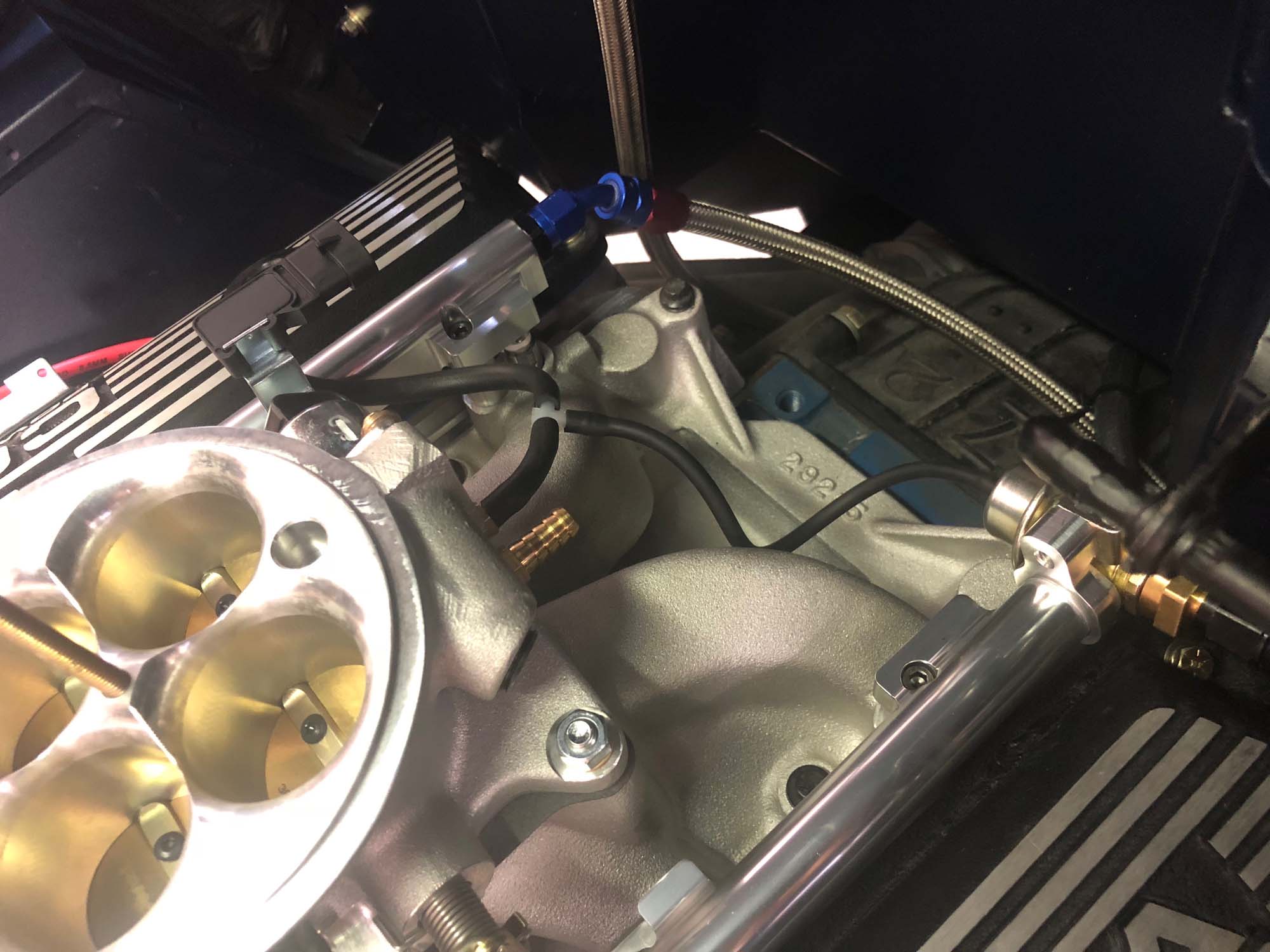

By comparison, the Edelbrock Pro-Flo 4 EFI is a far more precise method of fuel injection with individual injectors for each cylinder that are electronically synchronized with the intake valve opening events to deliver fuel into the air stream at the end of the manifold runners right before it enters the combustion chamber. This produces the absolute best fuel atomization with perfectly even distribution to each cylinder.

The multi-port design is so superior that, in 2017, Edelbrock discontinued production of their E-Street TBI kits in order to fully concentrate on the continued development of its Pro-Flo multi-port EFI product line.

So how much of a difference did the Edelbrock Pro-Flo 4 make compared to the Holley Sniper TBI on this classic Ford Bronco? Of course, we were just as curious as you are so after the Edelbrock-equipped Bronco was delivered to Dorvillier, we got in touch with him to get his initial impression of everything that he previously had issues with including cold-starting, idling, surging and stumbling under hard acceleration. This is what Dorvillier had to say:

“It’s a night-and-day difference! I can tell you that after driving it around the area, and my son also took it for a spin around our community, it’s more enjoyable to drive. I’m not fighting the darn thing anymore. I’m just driving it and enjoying it.”

And the best part is that the Pro-Flo 4’s self-learning fuel technology will continually adjust calibration and improve engine performance as the vehicle is driven, with no laptop tuning required. The system will automatically compensate for altitude and weather changes, and through the E-Tuner app, you maintain full control with the ability to adjust air-fuel ratios, ignition curve, idle speed, acceleration fuel, cooling fans, rev limiter RPM, and more. Or you can simply monitor the engine vitals in real time from the optional Android tablet or your smart phone.

Now that Mike Dorvillier is enjoying the newfound drivability with his Pro-Flo 4 EFI Bronco, we’re going to give him time to really get used to the system and follow up with a long-term driving impression in a few weeks.

For more information on the Pro-Flo 4 or other Edelbrock products, visit edelbrock.com.